Our application

Longridge Road Energy Centre is a new, privately funded £200 million Energy Recovery Facility (ERF) proposed for the Red Scar Industrial Estate (RSIE) on the edge of Preston. The project is being developed by Miller Turner.

The Energy Centre will have the capacity to export 42 Megawatts (MW) of low carbon electricity (and potentially heat) for distribution to businesses and other end users nearby. Distribution will be via the electricity grid, or a direct connection to businesses and other energy users – known as a ‘private wire’.

Longridge Road Energy Centre can produce dependable, local energy at lower prices, reducing costs for businesses in the area, helping to sustain existing employment in Lancashire and potentially attracting new employers.

Longridge Road Energy Centre will use the waste from households and businesses that remains after recyclable materials have been removed. In the UK, such leftover material, known as residual waste, is either landfilled, exported, or has energy recovered from it. By taking this leftover waste and using it to generate electricity, the Energy Centre can reduce waste going to landfill and reduce the region’s carbon footprint.

We have now submitted our planning application for Longridge Road Energy Centre to Lancashire County Council.

You can view all documents relating to the Planning Application by visiting planningregister.lancashire.gov.uk and searching for the application number: LCC/2019/0029

You can also view all the documents submitted with our planning application via the links below.

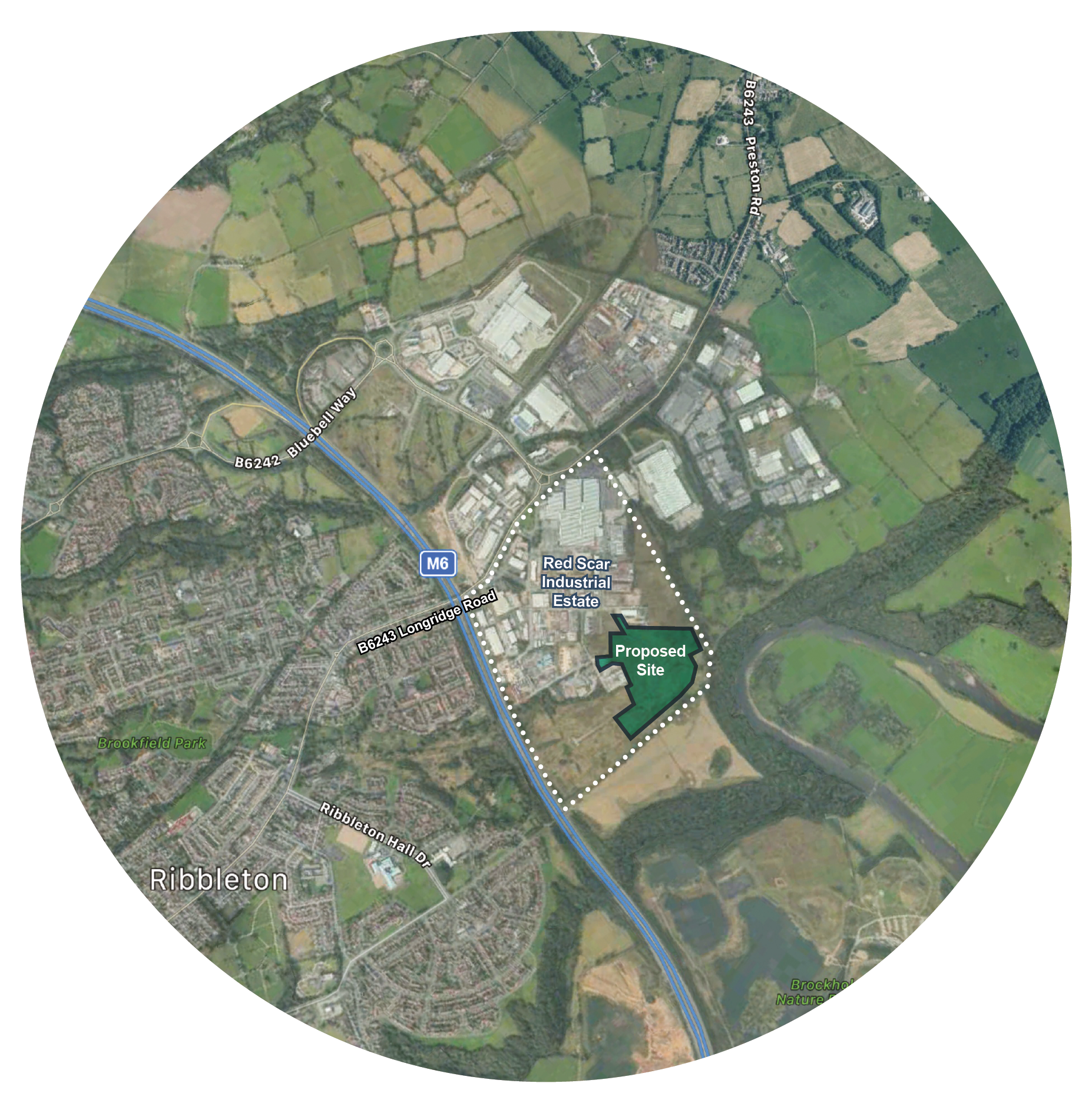

Location

Longridge Road Energy Centre is being proposed on the southern part of RSIE, formerly the location of part of the Courtaulds factory (PR2 5NE). The site is approximately 18 acres (7.3 ha) of undeveloped brownfield land. The closest site boundary is 300-350 metres east of the M6 motorway. The main buildings will be about 500 metres from the motorway at their closest.

The Energy Centre site is part of the currently un-redeveloped southern parts of the RSIE allocated for employment use in the Preston Local Plan. The RSIE, including the site of the proposed development, is also allocated for strategic waste management facilities, including energy recovery.

How energy recovery works

Longridge Road Energy Centre will take residual waste to use as a fuel to produce energy. Around 60% of the waste is biomass, making the energy that is generated from it low carbon.

The Energy Centre will use proven ‘moving grate’ technology in operation at a similar scale at hundreds of plants across the world, including about 40 in the UK. The combustion process produces heat, which is used to create steam. This then drives a turbine to generate electricity and recover the energy from the waste.

The electricity is then sold to the electricity grid, or to customers in the local area via a ‘private wire’ direct connection.

Longridge Road Energy Centre, as with other modern ERFs, will operate within a closely monitored, strictly regulated environment. The Energy Centre will offer numerous energy and environmental benefits such as:

Reducing our reliance on coal and gas for energy – helping to cut down our carbon emissions

Contributing positively to tackling climate change

Combined with recycling, contributing to minimising landfill and its harmful methane emissions

Reducing reliance on energy imports from abroad

Providing a dependable baseload electricity supply

Preventing odour emissions associated with uncontrolled waste-handling and treatment

Providing energy to local businesses at low and stable prices

Key benefits

Produces enough electricity to power up to 109,000 homes

Low carbon energy

Dependable source, generated locally

Potential to offer lower cost electricity via ‘private wire’

Up to 500 people employed during construction

40 permanent jobs

Apprenticeship opportunities

Potential to preserve or attract hundreds of new jobs by providing cheaper electricity to nearby employers

£200 million of investment

Requires no public subsidy

Significant additional business rates per year for Local Authorities

Predicted to lead to a net reduction in greenhouse gas emissions equivalent to approximately 77,000 tonnes of CO2 per year – the same as taking 28,500 cars off the road

Converts residual waste, destined for landfill, into power

Capacity to process up to 395,000 tonnes of residual waste per year

Reduces waste going to landfill in Lancashire, minimising harmful emissions

Topic information sheets

Ahead of our consultation events in March, we have produced a number of topic information sheets to help provide you with an extra level of detail about the proposals for Longridge Road Energy Centre.

You can download these from the buttons below.

FAQs

What is Longridge Road Energy centre?

Longridge Road Energy Centre is a new, privately funded £200 million Energy Recovery Facility (ERF) proposed for the Red Scar Industrial Estate (RSIE) on the edge of Preston.

How much Energy will be produced?

The Energy Centre will generate up to 40 Megawatts (MW) of low carbon electricity (and potentially heat) for distribution to businesses and other end users nearby. Distribution will be via the electricity grid, or a direct connection to businesses and other energy users – known as a ‘private wire’.

Longridge Road Energy Centre can produce dependable, local energy at lower prices, reducing costs for businesses in the area, helping to sustain existing employment in Lancashire and potentially attracting new employers.

Who are Miller Turner?

Miller Turner are the development team bringing forward proposals for Longridge Road Energy Centre. They have a track record of developing green energy plants in the ERF, biomass, wind and solar power sectors – including the 40MW Tilbury Docks wood-fuelled electricity generating station in East London.

What type of waste will be used?

Longridge Road Energy Centre will only use residual waste – the waste from households and businesses that remains after recyclable materials have been removed. Currently in the UK, residual waste is either landfilled, exported, or has energy recovered from it.

How much waste will the Longridge Road ENergy Centre take?

Longridge Road Energy Centre will have the capacity to process up to 395,000 tonnes of residual waste per year – helping to reduce the waste going to landfill in the area, and converting it into energy.

Will there be any air pollution or odours from the facility?

Longridge Road Energy Centre will use technology that is well established, closely monitored, and in use safely at numerous sites across the UK and abroad.

It will be constructed to the highest environmental standards and will be the subject of strict environmental regulations. These regulations will be embodied in an Environment Agency (EA) operating permit. The permit is issued after close scrutiny of a detailed application. The permit will require comprehensive environmental monitoring to be undertaken throughout the operational life of the Energy Centre. Monitoring results will be reported to the EA, who have the power to modify or halt operations if necessary.

All waste deliveries will be unloaded within the plant and lorries will be either enclosed or covered to prevent dust and litter. Any odours will be completely contained within the plant by maintaining negative air pressure in the waste reception building and feeding that air to the combustion chamber where odours are destroyed.

how will the local environment be considered?

A full Environmental Impact Assessment (EIA) will be undertaken to ensure that all matters relating to the environment are considered when developing Longridge Road Energy Centre. The EIA will be presented through the preparation of an Environmental Statement (ES), which will accompany the planning application that will be fully considered by the Local Planning Authority when deciding whether to support the development. A wide range of environmental subjects will be taken into consideration including air quality, traffic, landscape and ecology.

When the planning application is submitted, documents from the application suite and ES will be made available on this site.

What will the FACILITY look like?

Miller Turner is working closely with expert architects to ensure that the building’s layout and design reflects its proposed setting.

The design process for the building’s exterior will be iterative and will develop through consultation with Lancashire County Council, the public, and other stakeholders during the pre-application period. This includes seeking comments on areas external to the buildings, which will be landscaped and screened where appropriate.

As part of the EIA process, a Landscape and Visual Impact Assessment (LVIA) will be undertaken and explained in the ES in accordance with a methodology compliant with Landscape Institute and Institute of Environmental Management and Assessment Guidelines.

Although the design of the building is being finalised, the proposed development will include a building of up to approximately 35 to 40 metres in height, 170 metres in length and 70 metres in width. There will be one or two slim chimney stacks about 85 metres high and up to three metres in diameter. Plans and drawings of the building will be available on this website.

We will continue to update these numbers as the finalisation of the facility’s design is completed.

Key features to ensure that the facility is sustainable, modern and responds to its environmental setting include:

Bespoke buildings to fully enclose operations

Gas cleaning and emission-control equipment

Traffic management and noise abatement

Surface water management

Will there be increased traffic through residential areas?

The Energy Centre will have excellent road connections. RSIE can be accessed directly from Junction 31a of the M6 Junction and the B6242 Bluebell Way as well as the B6243 Longridge Road avoiding the need for traffic to be routed through residential areas.

Access within RSIE is purpose-built industrial estate roads right to the boundary of the site.

Will the facility impact on local ecology?

We are carrying out a comprehensive investigation of the ecological and biological features of the site and the surrounding areas. Longridge Road Energy Centre’s site is former industrial land that has been cleared and prepared for redevelopment. The design of the facility will include measures to enhance local biodiversity.

How will the local community benefit?

Longridge Road Energy Centre will create jobs during both its construction and operational periods. Once operational, it has the potential to help preserve nearby existing employment, and attract new employers to the area by providing cheaper electricity directly to local businesses. Measures will be included to ensure that employment opportunities are made available to the local workforce.

In addition, a community fund of £65,000 will be created to support projects that benefit local groups and people.

An education outreach programme will be developed, with education materials and site visits available. This will enable local school and college students to learn more about the energy recovery process, climate change, energy resources and biodiversity. Visitor centre facilities will be provided within the operational Energy Centre.

An apprenticeship scheme and training programmes will also be provided in support of an estimated 40 full-time operational roles.

Who will be responsible for operating the plant?

Miller Turner will form a separate company – a special purpose vehicle (SPV) – to take the project forward into the construction and operation phases. It is likely that the SPV will employ a highly competent and experienced operations contractor to manage and maintain the Energy Centre on a day-to-day basis on behalf of, and with the stringent oversight of, the SPV management team.

Who will take part in the Community Liaison Group?

Subject to formal planning approval being obtained, it is anticipated that the liaison group will be established prior to the start of construction. Alongside representatives from the Energy Centre owner/operator, other potential participants would be likely to include representatives from the local council(s) or recognised community groups within the local area.

Has a new access road from the motorway to the site been considered?

Slip roads off motorways are built for strategic purposes only and are not allowed to serve individual sites. The slip roads at Junction 31a were constructed to serve employment areas nearby and are designed to carry high volumes of traffic. The traffic generated by Longridge Road Energy Centre will be equivalent to around one per cent of the traffic using Junction 31a and would therefore not justify constructing a new slip road. Furthermore, motorways and trunk roads are designed to strict safety standards that would not permit an additional junction to be constructed due to the short length of motorway between the existing slip roads.

Is there a safe shut-down procedure for the Energy Centre?

Yes. A series of safety systems are in place that will ensure that operations can be safely shut down, should it be required. This process includes the ability to stop the fuel supply.

What happens in the case of an emergency?

Unlike a large chemicals manufacturing plant, Longridge Road Energy Centre is not classed as a hazardous facility and does not fall within the Control of Major Accident Hazards Regulations 1999. The fuel for the Energy Centre will be contained within a secure bunker fitted with infra-red cameras to monitor the waste and the fire suppression systems. It is very unlikely that a fire would occur, but if it did, the facility would be immediately shut down and the emergency services called.

What is the combustion temperature and how is it controlled?

The Industrial Emissions Directive requires that the temperature of the flue gases in the boiler reach a minimum of 850°C for a minimum of two seconds. Longridge Road Energy Centre’s Environmental Permit will include the same criteria. The temperature is monitored at multiple locations in the boiler. The design of the combustion chamber, the rate at which fuel is fed to the grate and, if necessary, the use of auxiliary burners, all ensure that the minimum combustion temperature is maintained.

Why is it important to control the combustion temperature?

As well as recovering value from residual waste by generating energy, Longridge Road Energy Centre is designed to destroy, treat and filter out potentially harmful substances and emissions. It will do so to very rigorous standards to protect the environment and health. Controlling the combustion temperature is an important part of that. The flue gas treatment system is a further safeguard to ensure that emissions are safe.

Will there be smoke or a visible plume from the stacks?

There will be no smoke visible as smoke particles will be filtered out by flue gas treatment. A visible plume (of condensed steam) may occasionally be visible, such as on cold days. An assessment of plume visibility has been undertaken as part of the air quality assessment and its impact predicted as low.

Will emissions be monitored continuously?

The scope and frequency of emissions monitoring will be stipulated by the Environment Agency (EA) in the Environmental Permit. It will require that a full range of emissions be monitored. The EA will require continuous monitoring of many of them. For some emissions, where their concentrations are too low for continuous monitoring to be feasible, samples will be taken and analysed in a laboratory. It is a mandatory requirement that monitoring results are reported to the EA regularly (quarterly for most emissions) and are then published in the EA’s public register.

Fact Check: Claims Relating to Longridge Road Energy Centre (LREC)

Claim: Emissions from LREC will cause cancer and damage health

Public Health England (formerly known as the Health Protection Agency) is a government body of leading UK independent scientific and public health experts. It focuses on advising government on public health matters. It considered a range of research undertaken into the impacts of energy recovery facilities in 2010 and again this year. In 2010 it concluded that ERFs of the type used in the UK produce a ‘…negligible impact on local air quality, and no measurable risk to health.’ It stated that it found no evidence to change this position in 2019.

Claim: Any level of pollutant emitted is dangerous, so filter technology doesn’t help

This is incorrect. Concentrations of substances matter enormously. Oxygen is damaging to health in its pure form, as is water if we drink sufficient quantities. The combustion design and filter technology employed in energy recovery facilities reduces pollutants to substantially below levels which would cause harm. The Environment Agency then sets and monitors strict legal limits for emissions that are safe and do not damage the environment.

Claim: It’s better to recycle plastics rather than burn them in LREC

We agree and we believe ways to reduce plastic waste should be found. LREC is designed to be able to operate and produce energy without plastics included in the residual waste fuel. Energy from waste is a source of low carbon energy – something increasingly in demand by companies buying energy.

Until other solutions are found, however, LREC removes low grade plastics that cannot be recycled and can end up in our environment. Plastic can also only be recycled a limited number of times, and energy recovery facilities are the best way to eliminate this plastic at the end of its recyclable life.

Claim: Burning waste in energy recovery facilities like the LREC will discourage recycling and reduce recycling rates

A number of countries with the lowest rates of ecologically harmful landfill have high rates of energy recovery and high rates of recycling. For example, Sweden sends almost no waste to landfill, has an extensive network of energy recovery facilities, and recycles over 50% of its waste – more than the UK currently achieves.

Claim: LREC would be the UK’s largest energy recovery facility

This is fundamentally untrue but has been claimed recently in literature distributed across local communities. LREC would process up to 395,000 tonnes of waste per year – the majority of which currently goes to landfill. This means it is within the typical range for capacity of a UK ERF. Other energy recovery facilities in the UK process up to 600,000 tonnes per year and the largest currently in operation processes over 1 million tonnes per year.

Claim: LREC will create odours that will impact on local communities

LREC is designed to prevent external odours that could affect local communities. Waste is only unloaded within the plant once it has been sealed, and negative pressures draw odours into the combustion chamber where they are burnt off at very high temperatures.

LREC will include a significant visitor centre for local people and school children to learn about waste, energy and the environment. We would not be proposing this if we were not absolutely confident of odour control measures.

Claim: 186 lorries will visit the LREC every day during operation

This is to confuse the figures. 93 lorries will make deliveries to LREC each weekday over a 12-hour period. This equals 186 separate movements. The majority of lorries will travel to LREC from the M6 motorway at Junction 31A and back again. The increase in traffic in the immediate vicinity of Red Scar Industrial Estate that results from the proposals is less than 1% of current traffic. The route between the M6 junction 31A and the site is built to carry HGV traffic.

Claim: Energy recovery facilities add to the problem of our climate change emergency

LREC is part of tackling climate change. By reducing landfill and displacing energy from fossil fuels with the low carbon energy it produces, the net effect of LREC operating would be the equivalent of removing 28,500 cars from our roads every single year by reducing carbon equivalent emissions by 77,000 tonnes per annum.

Timeline

Have your say

We will be running a pre-application public consultation for a period of six weeks from Friday 15 February to Friday 29 March 2019.

All feedback received during this period will be considered on an ongoing basis by the project team and suggestions will be incorporated into the scheme where possible.

We will be holding two public drop-in sessions to provide stakeholders and members of the public an opportunity to discuss the proposals with members of the project team on the following dates:

Wednesday 13 March 2019, 4pm - 8pm Norman Jepson Beefeater, Bluebell Way, Fulwood, Preston, PR2 5PZ

Thursday 14 March 2019, 10am – 2.30pm Norman Jepson Beefeater, Bluebell Way, Fulwood, Preston, PR2 5PZ

To find out more or to contact the Consultation Team for Longridge Road Energy Centre you can:

Call us on our freephone information line at 0800 032 1880

Email us at info@longridgeroadenergy.com

Write to us at Freepost LONGRIDGE ROAD ENERGY CENTRE

News

Plans Submitted for New £200 Million Preston Energy Recovery Facility - Low Cost Power, Jobs and Climate Change Benefits

A planning application has been submitted by Miller Turner to Lancashire County Council seeking permission to construct and operate a new £200 million energy recovery facility called the ‘Longridge Road Energy Centre’ (LREC) east of Preston.

If approved, the plant would be built on designated development land on the Red Scar Industrial Estate, just off junction 31A of the M6 motorway. LREC would have the capacity to export 42MW of sustainable, low carbon electricity from up to 395,000 tonnes per year of residual waste left over from household and commercial waste after recyclable material is removed. The new facility will generate enough power to supply the equivalent of up to 108,000 homes.

The plant will have the potential to provide electricity via ‘private wire’ directly to commercial and industrial customers in the locality. By supplying electricity directly to the customer, power can be provided securely and at lower cost, therefore improving the competitiveness of connected businesses and helping to create or sustain hundreds of jobs and attract new investment to the area.

Any surplus energy not sold directly to commercial customers will be distributed via the public electricity grid.

Currently, Lancashire buries most of its residual waste in landfill sites – a relatively high proportion compared to many other areas. By diverting residual waste from landfill and using it to generate electricity, LREC contributes significantly to the region’s ability to find practical ways to address climate change by saving the equivalent of 77,000 tonnes of carbon dioxide per year. This is equivalent to 28,500 cars or 570 million vehicle kilometers per year. LREC also helps to reduce harmful methane emissions, a greenhouse gas may times more damaging to the environment than carbon dioxide.

LREC will create 40 permanent jobs for the operation and maintenance of the plant as well as up to 500 jobs during the construction phase. Apprenticeships will also be offered.

A six-week public consultation on the plans was undertaken earlier this year, with information sent to local residents, the launch of a project website and public consultation events held locally to inform people of the plans and receive feedback.

Questions most often raised related to traffic, air quality and odours. High burn temperatures and extensive, tried and tested emissions control technology will ensure that emissions are tightly controlled to within regulatory limits and regularly monitored by the Environment Agency. This same technology also ensures that any odours are completely eliminated.

Traffic not originating in Preston will be routed to LREC via the M6, avoiding residential areas, with measures in place to ensure deliveries follow prescribed routes and managed to avoid peak traffic periods if necessary. It is anticipated that the relatively small number of journeys originating from within Preston itself will replace existing journeys to transport waste to landfill sites. Additional proposals for the development include on-site biodiversity enhancements to improve the ecological value of the land, which is currently poor.

Commenting on the application, Gregory Ewing, Chief Executive Officer for Miller Turner, said: “Our team has extensive experience of delivering sustainable energy projects like Longridge Road Energy Centre in the UK. It will use well-proven, modern, efficient technology which is currently in operation at numerous energy recovery facilities across the UK and Europe. The plant will operate under a strict licensing system administered by the Environment Agency.

“We have been careful to ensure our proposals address any questions raised in the consultation and we have updated the website continuously as our proposals have been developed. Furthermore, in support of our local community we are proposing a community fund of £65,000 a year to help support local initiatives and projects.

“LREC has the potential to significantly reduce landfill, carbon and methane emissions and create and protect hundreds of jobs. The location of the site offers significant opportunities for local businesses to benefit from the low cost, sustainable energy LREC will recover. We are pleased to be submitting our application and look forward to progressing this important project.”

Pre-APPLICATION consultation begins for Longridge Road Energy Centre

We will be running a pre-application public consultation for a period of six weeks from

Friday 15 February to Friday 29 March 2019.

All feedback received during this period will be considered on an ongoing basis by the project team and suggestions will be incorporated into the scheme where possible.

We will be holding two public drop-in sessions to provide stakeholders and members of the public an opportunity to discuss the proposals with members of the project team on the following dates:

Wednesday 13 March 2019, 4pm - 8pm Norman Jepson Beefeater, Bluebell Way, Fulwood, Preston, PR2 5PZ

Thursday 14 March 2019, 10am – 2.30pm Norman Jepson Beefeater, Bluebell Way,

Fulwood, Preston, PR2 5PZ

Contact us

To find out more or to contact the Consultation Team for Longridge Road Energy Centre you can:

Call us on our freephone information line at 0800 032 1880

Email us at info@longridgeroadenergy.com

Write to us at Freepost LONGRIDGE ROAD ENERGY CENTRE